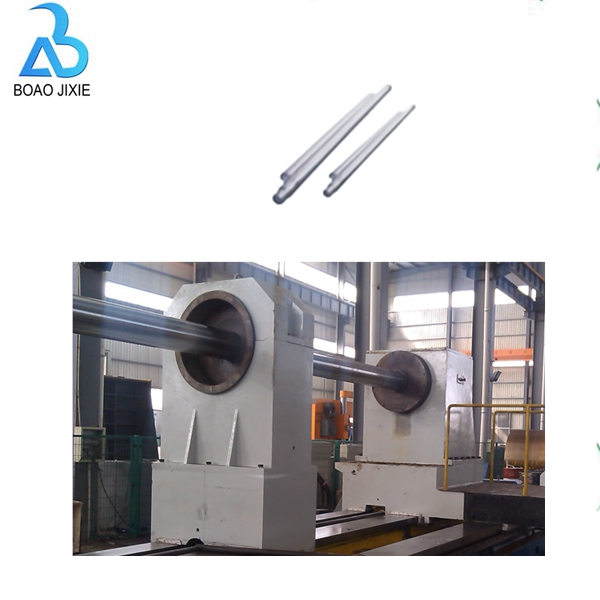

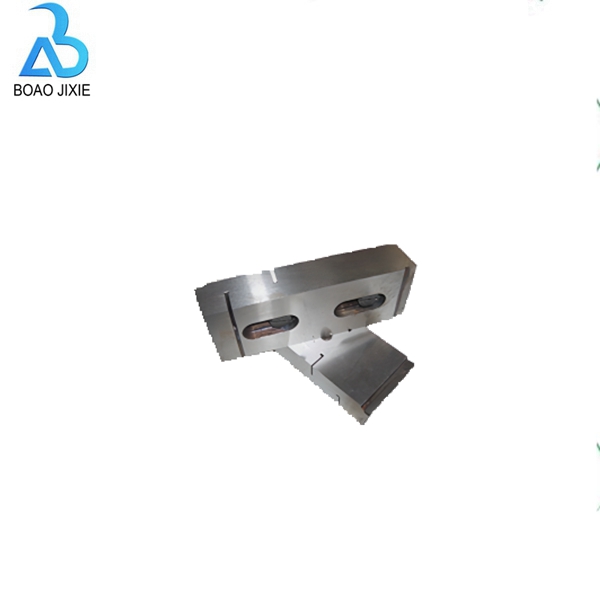

ZT type Casing Drilling bit ,Reaming Boring Head

Product Description

Casing Drilling bit is also named as annular drill, it is an economic,productive and high quality deep hole tool.Its productivity is more than 10 times the ordinary drill. It is better to use casing drilling bit for machining the hole above 50mm in diameter.This tool is applicable to the following conditions:

(1)Hole diameter is 50mm above,and with the close tolerance on straightness and position precision

(2) The length-to-diameter ratio of the hole is in the range of 1~75, it is the better choice to use casing drilling bit head than other machining methods.

(3)The job material is very expensive and the core needs measuring and chemical analysis,and the entire core mandrel needs to be reserved.

(4) The machine power is not enough if drilling the big hole,so the trepanning is the good choice. It is suitable for the diameter ranged from 50 to 600mm (thematching tool bar should be also deployed).

|

NO. |

Problems |

Reason |

Solution |

|

1 |

Machining chip is too small |

wrong cutting data

|

Adjust Speed and Feed |

|

Wrong chip breaking geometry, ellipse angle too small or too deep

|

Change cuter slot types |

||

|

Workpiece material instability |

Adjust Speed and Feed |

||

|

Poor initial cutting (workpiece not centered) |

Position hole center |

||

|

2 |

Machining chip is too big |

wrong cutting data |

Adjust Speed and Feed |

|

Wrong chip breaking geometry, ellipse angle too small or too deep |

Change cuter slot types |

||

|

3 |

Machining chips are not same |

Workpiece materials are not same |

Change cuter slot types |

|

Wrong feeding way ( hydraulic feeding ) |

Check with manufacturer |

||

|

Cooling is not good |

Make cooling bigger |

||

|

Strong vibration caused by insufficient rigidity of the workpiece and tool The material of the workpiece is unstable |

Check with manufacturer |

||

|

4 |

Fibrous iron filings |

Workpiece materials are not same |

Change cuter slot types |

|

Wrong feeding way ( hydraulic feeding ) |

Check with manufacturer |

||

|

Insufficient coolant |

Clean coolant |

||

|

Chemical affinity reaction between workpiece and carbide tool |

change |

||

|

chip edge chipping |

change |

||

|

feed too low |

Improve feeding |

||

|

5 |

Chipping of cemented carbide inserts |

Cutter is not fast |

Change |

|

Coolant doesnt work well |

Check flow and pressure |

||

|

Insufficient coolant |

Check coolant |

||

|

Guide bushing tolerance is too small |

Change |

||

|

Drilling bar and spindle are eccentric |

Change to eccentric |

||

|

Wrong cutter parameter |

Change |

||

|

Workpiece materials are not stable |

Set suitable speed and feeding |