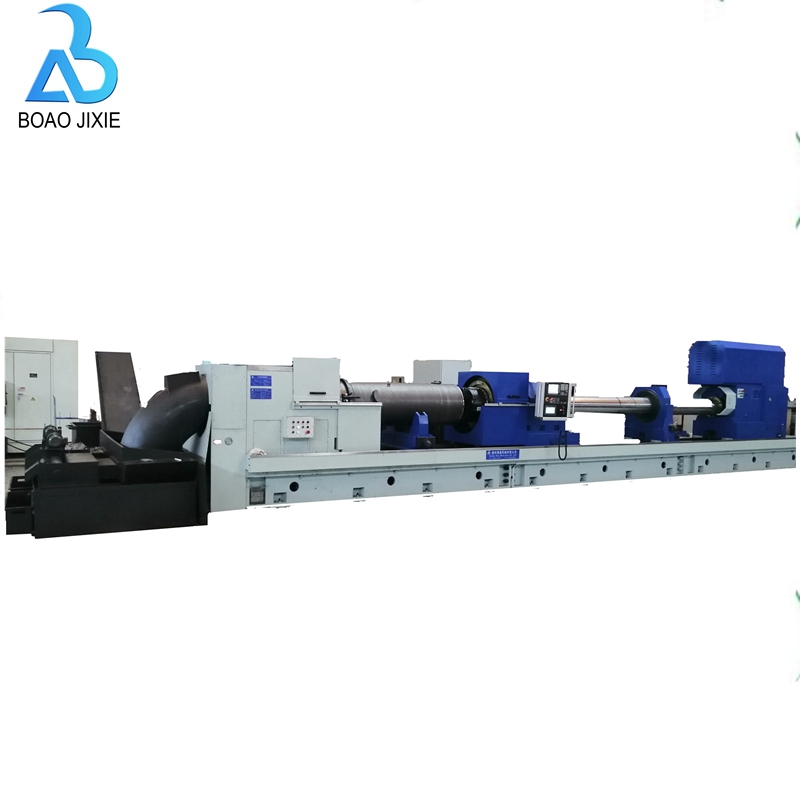

Custom TGK Series Deep Hole CNC Advanced Boring Machine

Machine Character

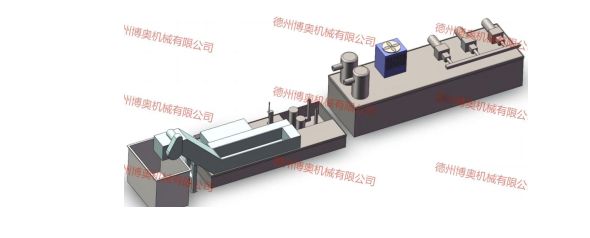

We are a professional deep hole equipment manufacturer in China, with rich manufacturing and design experience. For large and deep holes larger than 360 mm, we can provide personalized customization services.

All our machines use strong metal structure and good quality electric elements to make. We design protection system in the machine processing to protect operators . Our professional engineers team have designed many machines to our customers in this so long time. As China digital industrial requirement , we also have finished some automatic production line for some customers. All would be known after you contact with us.

Important Machine Parts

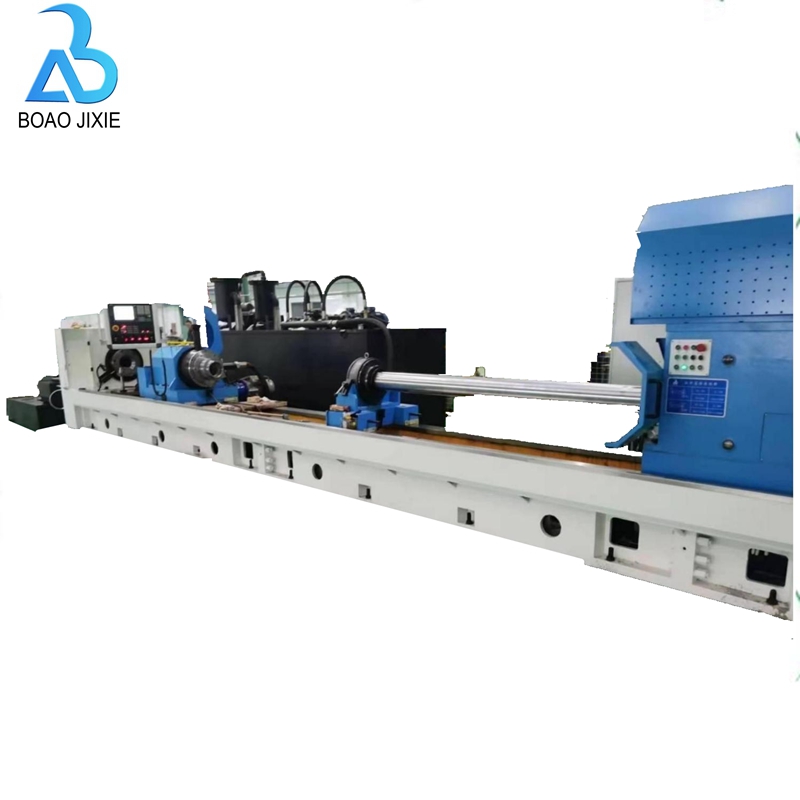

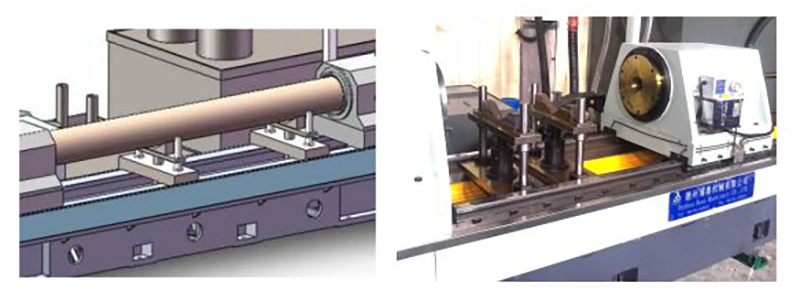

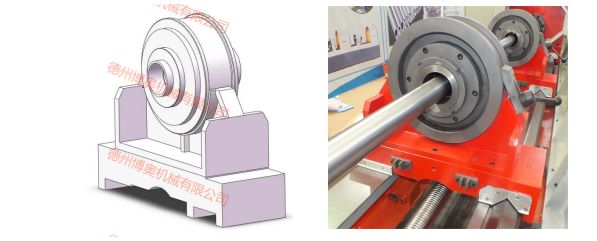

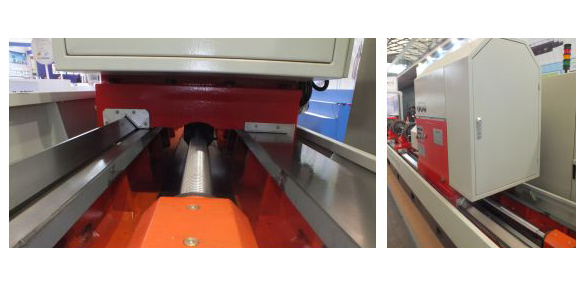

1. Enginee bed and workpiece bed

The boring bar box is an important part of machine , to supply the power to boring heads. So we use good quality parts and improve the structure design to make machine work well.

Boring rod would be hold by the fixture clamping.

The workpiece tubes are in another bed, so that the boring head could go to deep hole to cutting.

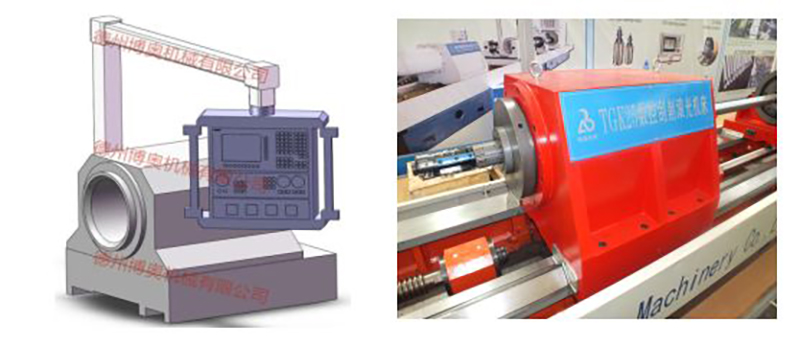

2. Machine Feed System

Taiwan Shangyin high-precision ball screw pair is installed in the middle and rear half of the groove of the machine tool body, and there is a feed box at the end, driven by a 5.5KW AC servo motor, to realize the feeding of the tool by the feed pallet (boring bar box). The feed speed can be adjusted steplessly, and the tool can be retracted quickly. The front half of the groove of the machine bed body is equipped with a T-shaped screw and a feed box, which are used for feeding the oil return device, adjusting the workpiece position and clamping. The entire feeding system has the advantages of high precision, good rigidity, smooth movement, and good precision retention.

3. Machine coolant & filter system

The machine tool has a three-step filtration system to purify the cutting fluid to the greatest extent and separate waste chips. During the machining process, the machine will continuously spray and collect cutting fluid. There is an oil tank at the end of the machine to collect waste debris, which can be removed in time.

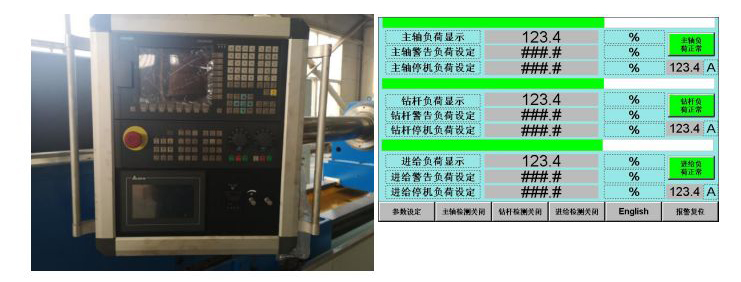

4. Machine Operation

The equipment provided by our company is equipped with a Siemens operating system. The operating system is designed by our company according to the usage conditions of our customers, which makes the use of the machine more concise and efficient. We will provide machine tool operating instructions and video explanations, so that our customers can use our equipment without worry. The control interface of the machine tool is displayed to most customers in English, if you need a customized language, we can also provide it. Most of the electrics of machine tools use high safety factors, stable quality, and international first-line brands. It can also be customized according to customer needs.

Our projects