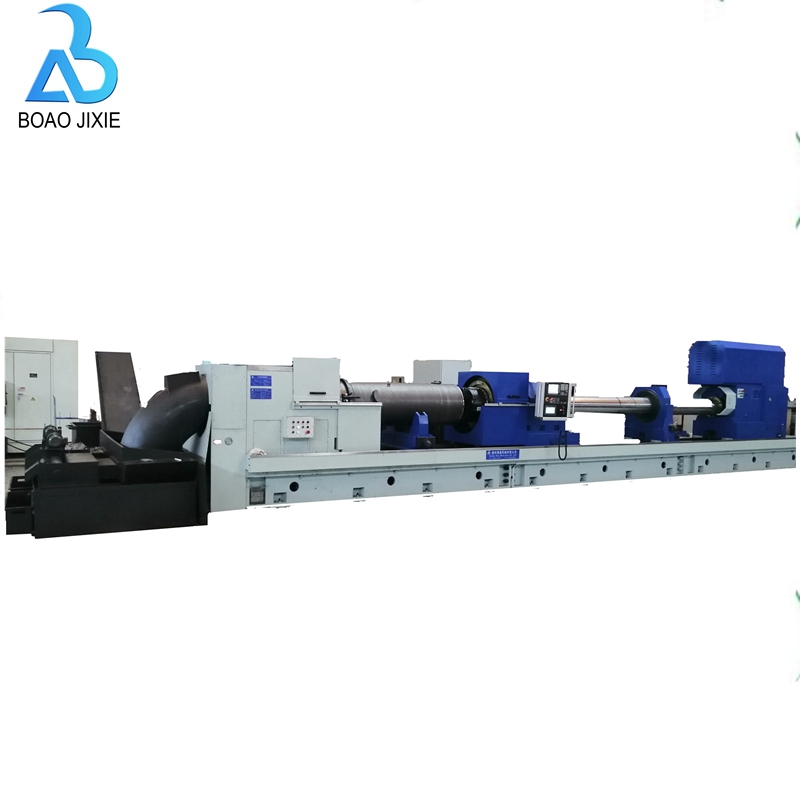

TGK 36 Deep Hole CNC Advanced Boring & Grinding Machine

Machine Character

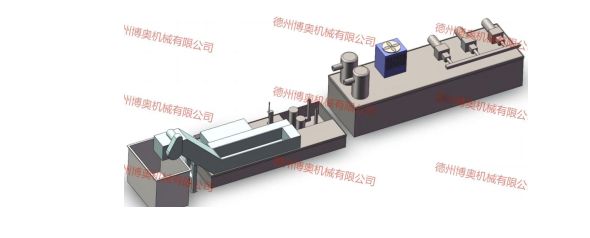

TGK25 series CNC skiving & rolling machine tool adopts the processing method of fixed workpiece and rotary feed of tool. The machine tool can realize the boring, scraping and rolling processing of the inner holes of the workpieces, the processing way is simple, and the processed products are high precision. The main advantages of this machine tool are high processing efficiency, stable performance, and the efficiency is 5 to 10 times of traditional deep hole boring machines and honing machines; the degree of intelligent control is high, and the digital control and monitoring of each action command of the machine tool are simple and convenient. easy to operate.

TGK25 series machine tools are equipped with Siemens 828D numerical control system; the spindle box is driven by AC servo motor with stepless speed regulation, and the spindle bearing adopts high-precision bearings with high rotation accuracy. The feed box adopts an AC servo motor with stepless speed regulation; it is equipped with a high-precision ball screw to realize high-precision and stable feed of the spindle box. The CNC scraping and rolling machine is equipped with a high-efficiency automatic expansion and contraction scraping and rolling tool, a special pneumatic and hydraulic tool retraction system, the workpiece is fixed, and the external chamfering of the two ends of the cylinder is used as the positioning basis. The inner hole is completed with one-time boring, scraping and rolling processing. The equipment should not only be suitable for the use of ECOROOL hydraulic scraping head, but also suitable for the use of pneumatic scraping head. This project is a turnkey project. This equipment is especially suitable for mass processing of various hydraulic cylinders, cylinders and other precision pipe fittings.

Machine Parameters

|

NO |

Items |

Description |

|

1 |

Processing Inner Diameter Range |

Φ60-360mm |

|

2 |

Processing Depth Range |

1000mm-12000m |

|

3 |

Machine Guideway Width |

650mm |

|

4 |

Spindle Center Height |

450mm |

|

5 |

Spindle Speed, Grades |

60-1000rpm, 4 gears, stepless |

|

6 |

Main Motor |

45/60/75KW, AC servo motor |

|

7 |

Feeding Speed Range |

5-3000mm/min ( stepless ) |

|

8 |

Carriage Fast Moving Speed |

3000/6000mm/min |

|

9 |

Fixture Clamping Range |

Φ120-450mm |

|

10 |

Feed motor |

48N.m(Siemens AC servo motor) |

|

11 |

Coolant System Motors |

N=7.5kw 11kw 15kw |

|

13 |

Coolant System Rated Pressure |

2.5MPa |

|

14 |

Coolant System Flow |

200L/min、200L/min、200L/min ( 3 sets) |

|

15 |

Hydraulic System Rated Pressure |

7 MPa |

|

16 |

Air Pressure |

≥0.4MPa |

|

17 |

Control System |

Siemens |

|

18 |

Power Supply |

380V. 50HZ, 3 Phase ( Customize) |

|

19 |

Machine measure |

L*2400*2100*( L*W*H) |

Important Machine Parts

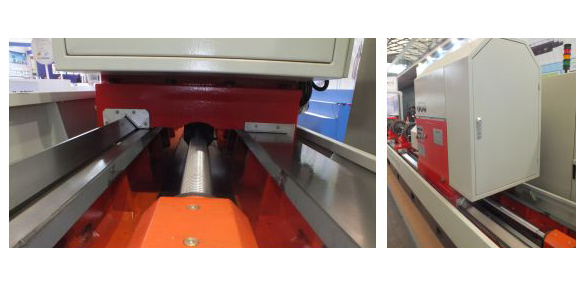

1. Machine Bed

The bed adopts double rectangular flat guide rail structure, and the guide rail width is 650mm. The bed body is the basic component of the machine tool, and its rigidity directly affects the working performance and working accuracy of the whole machine tool. Therefore, the bed of this machine tool is molded with resin sand and cast with high-quality cast iron HT300. It has good appearance and strength. The layout of ribs is reasonable. The outer side of the bed is cast with a backflow groove, and a protective cover is installed on the outer side, which has good appearance protection performance and no oil leakage. It can effectively collect cutting fluid and return it together for repeated use. The bed adopts split splicing structure, and the guide rail adopts intermediate frequency quenching (hardness not less than HRC50, hardening depth not less than 3mm) and then grinding process, which makes the machine tool have good wear resistance and precision retention.

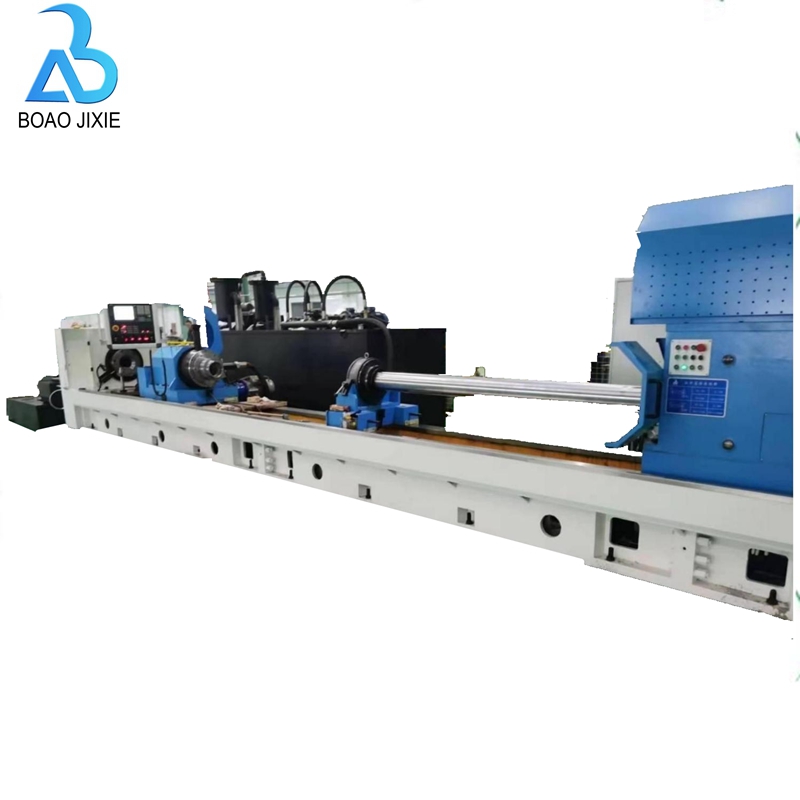

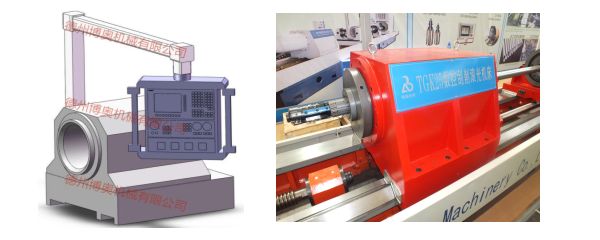

2. Boring Rod Drive Box

The boring bar box is an integral casting structure and is installed on the feed pallet. The spindle is driven by a 45KW AC servo motor, and spindle rotation is driven by the synchronous belt driven by speed change mechanism. The speed range is 3-1000r/min, 4 gears, hydraulic automatic shifting stepless speed regulation. The choice of rotational speed can be determined according to factors such as workpiece material, hardness, cutting tool and chip breaking condition. According to different speeds, it can be set through the programming of the numerical control system, and the spindle bearings are selected from imported brands such as N SK in Japan. The main function of the boring bar box is to drive the tool to rotate

3. Oil Feeder System

Located in the middle of the machine tool. The main functions of the oil receiver part are: 1. Input coolant to the workpiece. Second, support the boring bar to reduce the vibration of the tool bar during processing. Third, the front end of the oiler is equipped with a tool guide sleeve on the top plate of the workpiece, which can realize the guide of the entrance when the scraping tool is processed. Fourth, after the oil receiver is positioned on the bed body, it presses the workpiece hydraulically through the oil return device, and jointly plays the role of pressing and sealing the end surface of the workpiece and self-centering. The guide sleeve and the cone are required to be hardened, and the hardness is required to be above HRC45.

4. Oil Collector System

Located at the left end of the machine tool, it can move along the axial direction of the bed body and be fixed in position. The main function of the oil return device is: the end face is pressed against the workpiece to realize the centering of the processed workpiece and the end face seals the coolant to prevent the cutting fluid from splashing; in addition, the cutting fluid is wrapped with chips during the machining process, and passes through the inner hole of the oil return device through the chip discharge tube Flow into the automatic chip conveyor. The lower part of the oil return body is connected with the T-shaped screw in the middle of the bed body, and the axial movement realizes the pre-positioning of the workpiece during the processing; it is equipped with a servo motor jacking device (because the jacking adopts the most advanced servo motor jacking, which replaces the The hydraulic jacking method enables the adjustment of the jacking force to truly realize digital control. The wall thickness and diameter of the workpiece are different, and different jacking forces are selected to prevent the nozzle from deforming to the maximum limit. ), to realize the centering and sealing of the processed workpiece , The hardness of the cone disc is required to be above HRC45, and the coaxiality between the top disc and the front top disc on the pressing seat is less than 0.05mm.

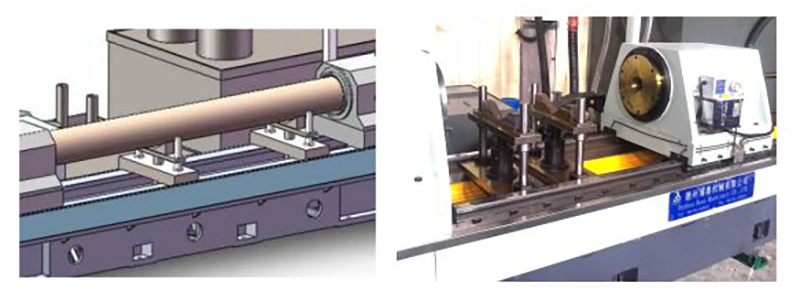

4. Machine Feed System

Taiwan Shangyin high-precision ball screw pair is installed in the middle and rear half of the groove of the machine tool body, and there is a feed box at the end, driven by a 5.5KW AC servo motor, to realize the feeding of the tool by the feed pallet (boring bar box). The feed speed can be adjusted steplessly, and the tool can be retracted quickly. The front half of the groove of the machine bed body is equipped with a T-shaped screw and a feed box, which are used for feeding the oil return device, adjusting the workpiece position and clamping. The entire feeding system has the advantages of high precision, good rigidity, smooth movement, and good precision retention.

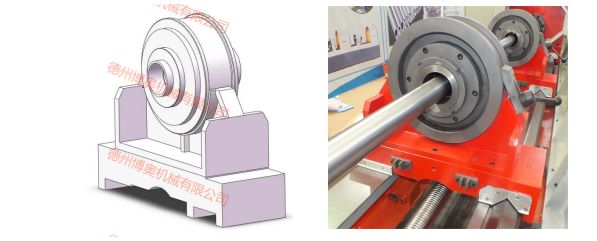

5. Boring Bar Support System

The supporting sleeve of the boring bar is fixed on the bracket body with screws, and is replaced together with the boring bar, which is convenient and quick to replace different boring bars. It mainly plays the role of supporting the boring bar, controlling the moving direction of the boring bar, and absorbing the vibration of the boring bar. Internal support sleeve with swivel function.

6. Workpiece Fixture Support System

Equipped with two sets of V-shaped block brackets to support the workpiece. The screw and nut lifting can be adjusted arbitrarily according to different workpiece diameters. It mainly plays the role of workpiece load-bearing and adjustment, and the position of the boring hole

7. Hydraulic System

The machine tool is equipped with a special hydraulic system, which is used to control the expansion and contraction of the hydraulic tool and the hydraulic automatic shifting of the boring bar box to complete the control system of the rolling action. The rated pressure is 7Mpa. The main components are imported oil research series products.

8. Coolant Filter System

Cooling chip removal and filtration system: mainly located at the rear of the machine tool, after filtering by chain plate automatic chip removal machine (coarse filter)→first-level oil filter→second-level oil filter and third-level filtration after sedimentation and filtration. The iron chips are sent to the chip storage car by the chain plate chip conveyor, the coolant flows back to the oil tank, and then the coolant is supplied to the oil receiver through the cooling pump station, and the oil is supplied by 3 sets of vane pumps to meet the different needs of the workpiece hole size.

When machining the inner hole of the workpiece, the main shaft of the boring bar box drives the tool to rotate, and the iron chips are carried forward by the coolant and discharged through the inner hole of the oil return device. The automatic chip removal machine sends the iron chips to the chip storage car, and the coolant is collected and recovered Reuse.

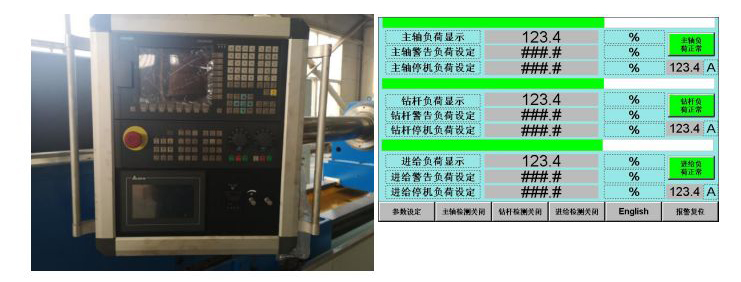

9. Machine Operation

The machine tool operation control panel is installed on the pressing seat and fixed on the pressing seat carriage, which is convenient for machine tool operation. The panel is made of matt brushed stainless steel, the shape is overall coordinated, beautiful and durable.

The machine software is designed in Siemens and applied for many years. We keep advanced as global level.

10.Electric System

It consists of main control box, operation box, terminal box and cables. The main electrical components are Schneider brand. For electric control box (air conditioning cooling). The main wiring part adopts aviation plug structure. The cables adopt the national standard, and the weak current cables adopt the shielded cables. The wiring is arranged in strict accordance with the strong and weak electrical isolation.

|

NO |

Items |

Brands |

NO |

Items |

Brands |

|

1 |

Machine metal body |

Self-made |

2 |

Boring bar drive box |

Self-made |

|

3 |

Support panel |

Self-made |

4 |

Spindle bearing |

Japan NSK |

|

5 |

Other bears |

Good brands |

6 |

Ball screw |

Taiwan brand |

|

7 |

Main electric elements |

schneider or siemens |

8 |

Spindle motor |

China brand |

|

9 |

Feed servo motor |

Siemens |

10 |

Feed servo driver |

Siemens |

|

11 |

CNC system |

Siemens |

12 |

Pneumatic elements |

Japan SMC |

10.CNC Control System

The machine tool is equipped with SIMENS828D CNC system, and the coolant pressure is displayed by instruments. The feed motor is a servo motor, and the boring bar box motor is imported. Manual feed, self-diagnosis function. Status Display,

Various functions such as current position display, program display, parameter setting display, alarm display, multilingual display conversion, etc. With RS232/USB interface, it can be programmed outside the machine. Equipped with a program input and output interface, which can be dumped and stored on the computer. Configure the main control panel and operation button station, Chinese operation interface and operation switches, buttons, etc. The main control graphic man-machine interface is used to monitor the status of the equipment, display faults and other management information. With self-diagnosis, self-protection function, equipped with LCD display.

In addition, a separate tool protection module is installed: Taiwan Delta PLC + man-machine dialogue touch screen is used to monitor the tool running status in real time. When the tool running exceeds the preset value of the normal state in advance, the machine tool tool protection will alarm in two stages Prompt or stop automatically, and can intuitively observe the running status of the moving parts of the machine tool, which is beneficial to the protection of tool damage and the safety of workpiece processing. The parameter setting is simple, intuitive, convenient and reliable. A PLC tool protection function module is added to effectively avoid the phenomenon of "tool locking".